EBS Reports

Reports

You can write an SQL query for Oracle EBS and save it as a local database report. The application uses several seeded reports for transaction purposes. For example, to create a PO receipt, you need to search pending receiving orders, and that report is a simple SQL query. This section describes how to view existing reports, modify them and create new reports.

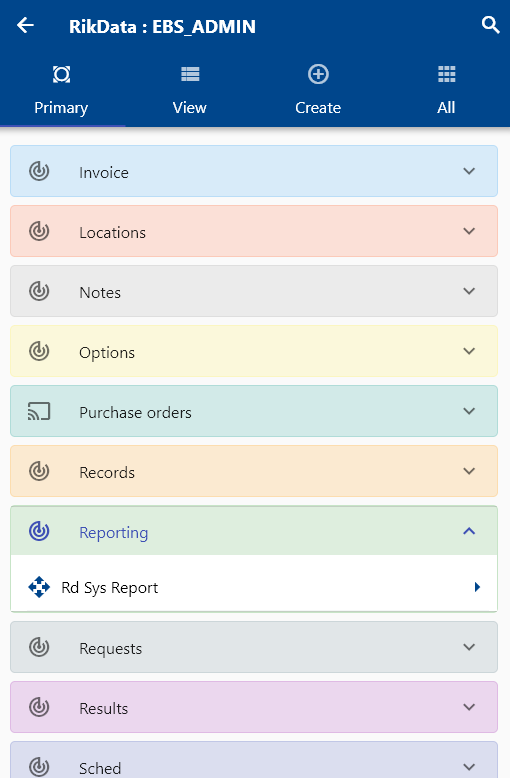

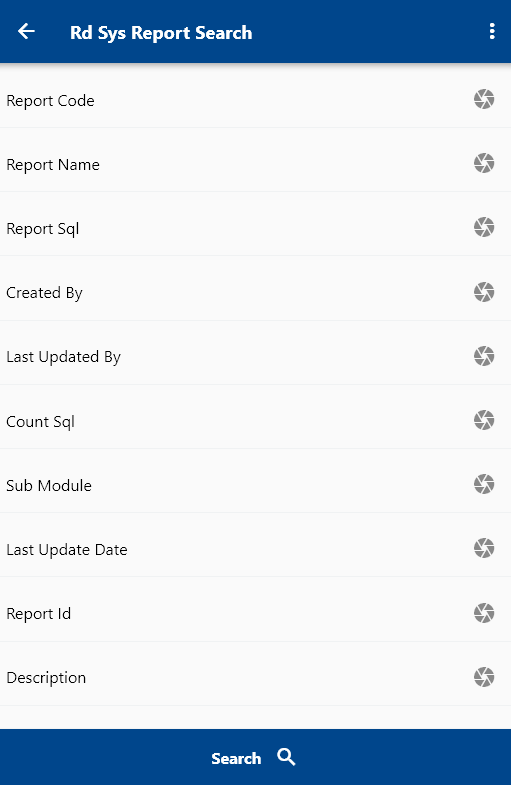

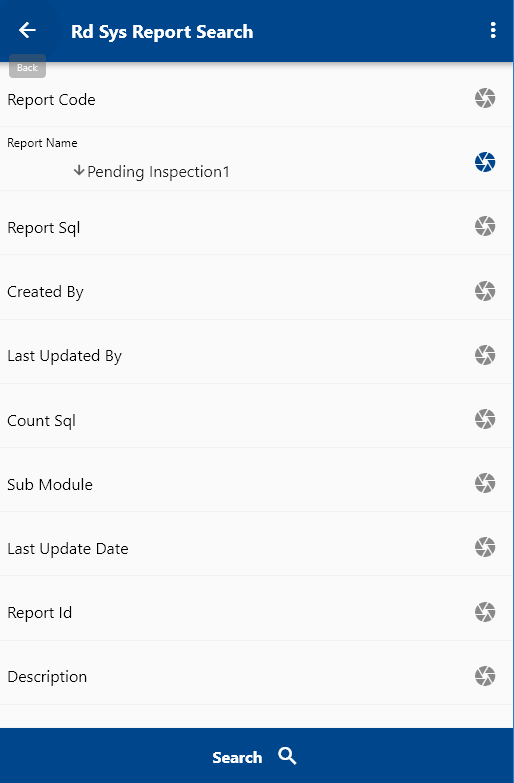

To create a new report or change an existing report, navigate to the report search form.

Enter a value in any search criteria in the search form and click on the search button.

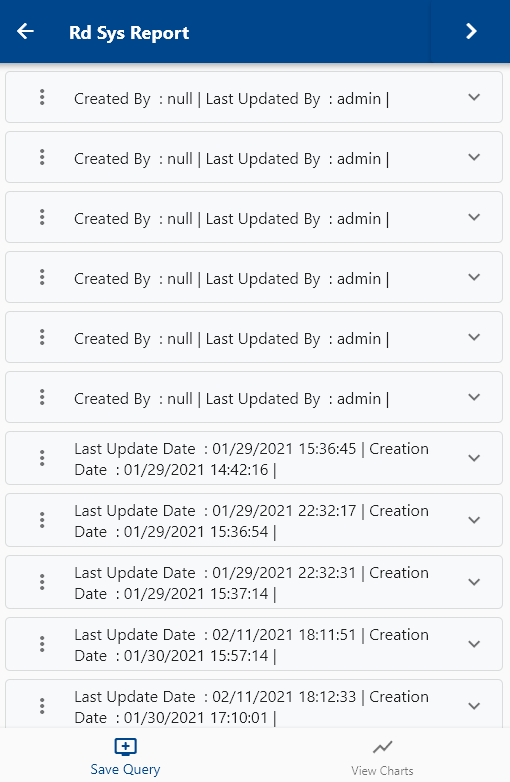

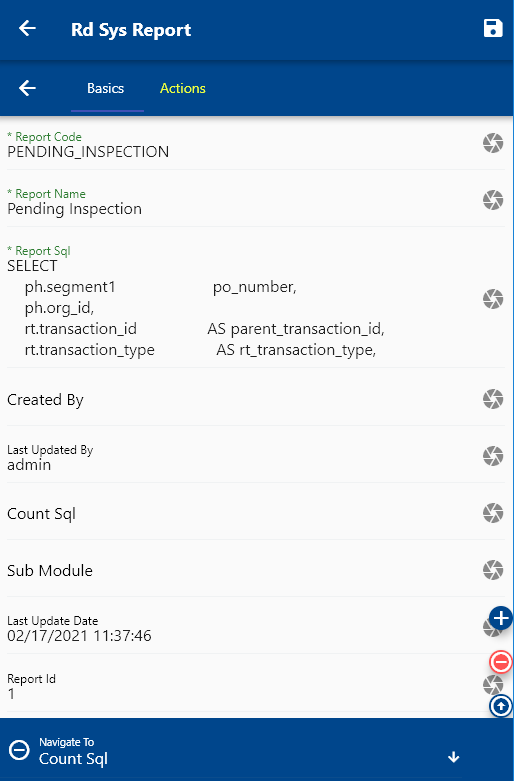

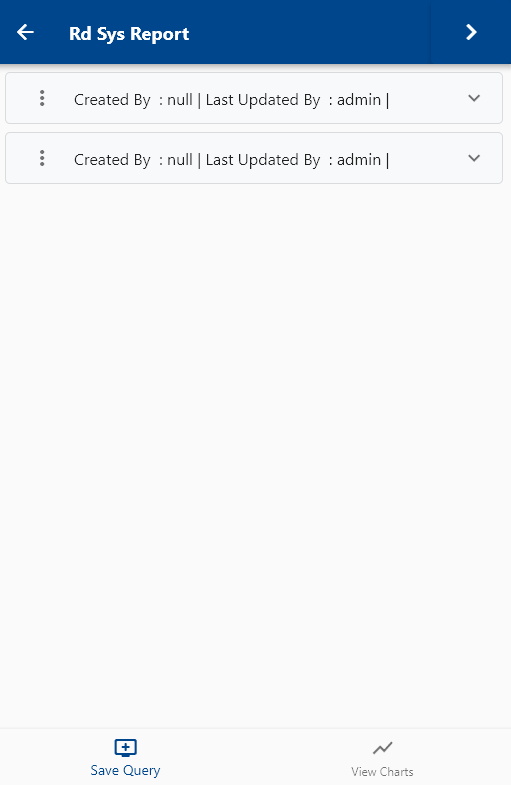

Click on the expand button to view any report details.

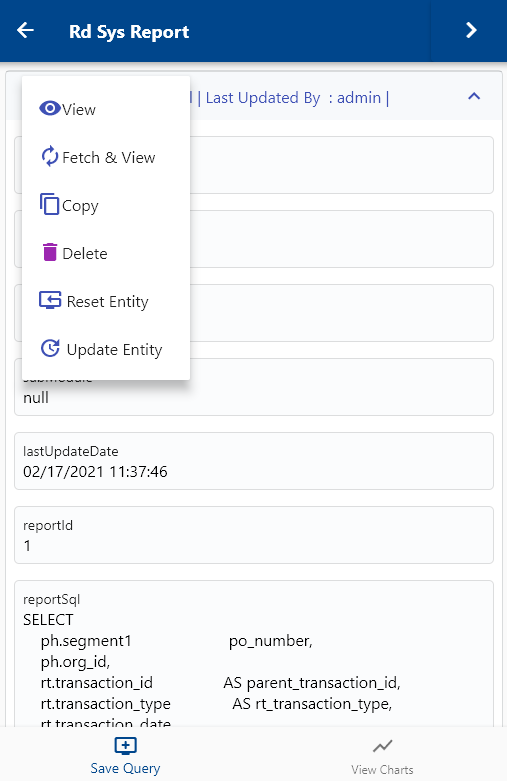

Click on view or fetch and view to view the report details in the report screen.

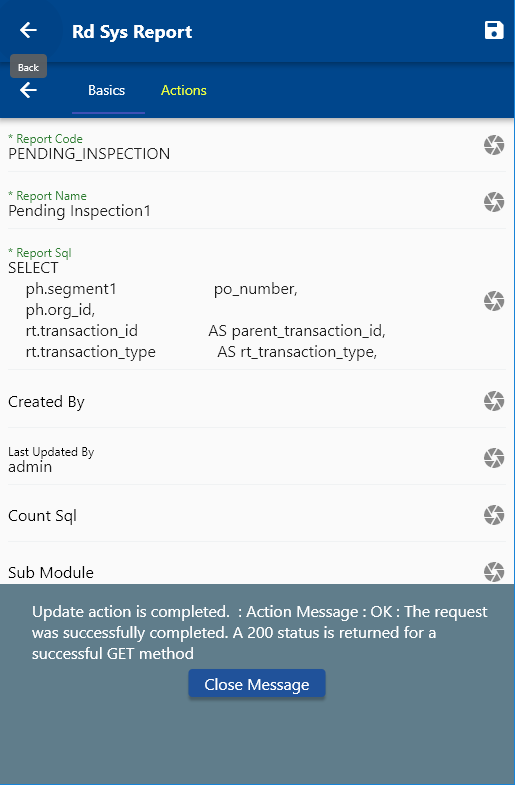

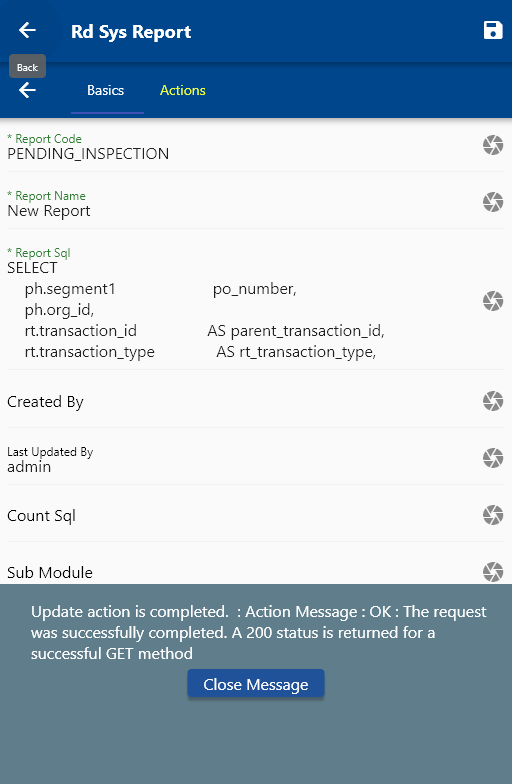

Make any changes as required and click on the Save button.

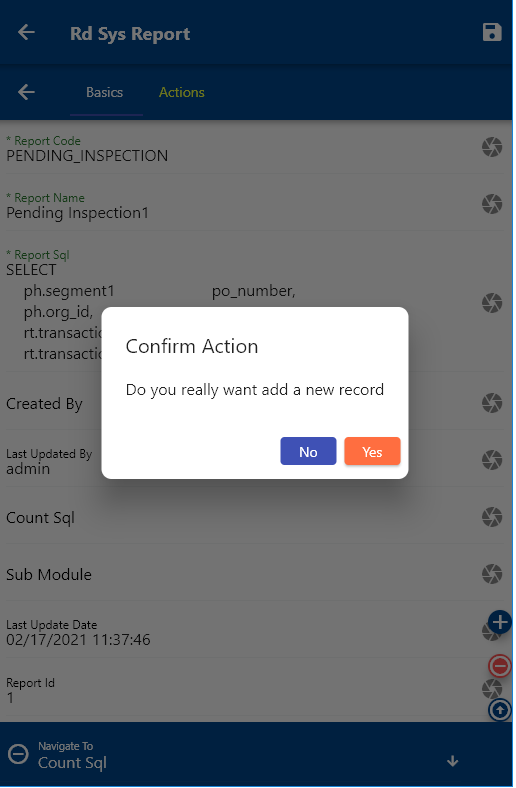

To add a new port, click on the add button.

Click on yes, to create a new report. Click on no to cancel the action.

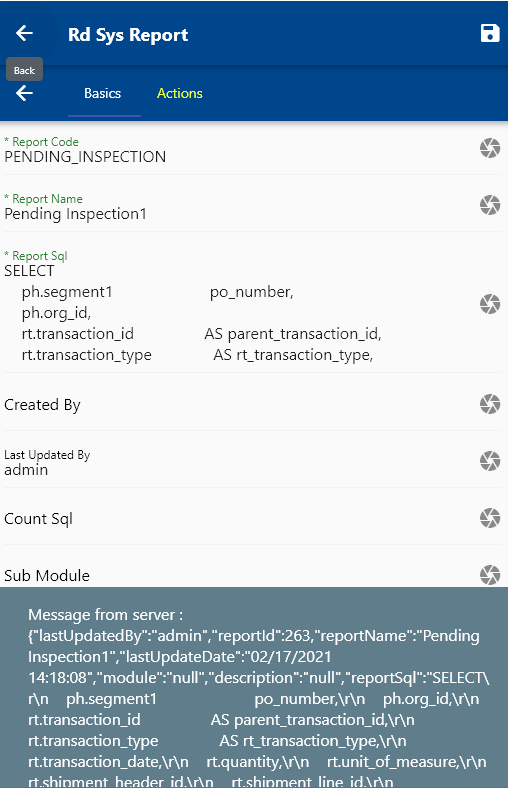

If you click on yes, the application will copy all the data from the existing report and will create a new report.

You need to change the details of the newly copied report as per your requirement.

Navigate back to the report search form and search with the original report name.

The app will show two reports with the same name: the old one and the new one. The new report's report id will be a higher number than the old report's id.

Select the new report and click on view.

Modify the details of the new report and click on save.

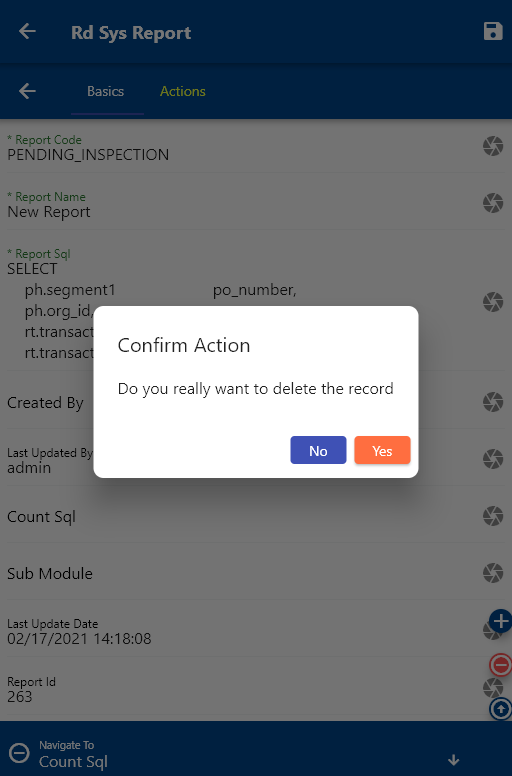

To remove a report, click on the delete button against the report.

Click on yes, to delete the report. Click on no to cancel the action.

Pending Receiving

The pending receiving report shows all the items waiting for receiving. Below is a sample SQL; you can modify it as per your business requirements.

SELECT

'PO' AS doc_type,

'RIKTRX' AS SOURCE_CODE,

'1' AS process_flag,

'2' AS lock_flag,

'3' AS transaction_mode,

'35' AS transaction_type_id,

'1' AS transaction_action_id,

'5' AS transaction_source_type_id,

'SYSDATE' AS creation_date,

'SYSDATE' AS last_update_date,

ph.segment1 AS po_number,

pl.line_num,

pll.shipment_num,

pv.vendor_name,

ph.currency_code,

ph.authorization_status,

pll.quantity - nvl(pll.quantity_cancelled,0) - nvl(pll.quantity_received,0) transaction_quantity,

msi.segment1 AS INVENTORY_ITEM,

pl.item_description,

pl.line_type_id,

DECODE(pll.receiving_routing_id,1,'STANDARD',2,'INSPECTION',3,'DIRECT',0,'NONE') routing,

DECODE(pll.receiving_routing_id,1,'RECEIVE',2,'RECEIVE',3,'DELIVER',0,'RECEIVE') AUTO_TRANSACT_CODE,

'RECEIVE' TRANSACTION_TYPE,

pd.destination_type_code,

pd.destination_subinventory,

NULL destination_locator,

NULL destination_locator_id,

pd.destination_organization_id as organization_id,

pl.purchase_basis,

pl.matching_basis,

pl.quantity line_qty,

pll.quantity,

pll.quantity_received,

pll.quantity_accepted,

pll.quantity_rejected,

pll.quantity_billed,

pll.quantity_cancelled,

ph.comments,

ph.document_creation_method,

ph.segment2,

ph.segment3,

ph.vendor_id,

ph.vendor_site_id,

ph.ship_via_lookup_code,

ph.fob_lookup_code,

ph.freight_terms_lookup_code,

ph.note_to_authorizer,

ph.note_to_vendor,

ph.note_to_receiver,

ph.vendor_order_num,

ph.org_id,

nvl(pll.promised_date,pll.need_by_date) AS promisdate,

pl.closed_code,

pl.unit_price,

pl.item_id as inventory_item_id,

pl.item_revision,

pl.unit_meas_lookup_code,

msi.PRIMARY_UOM_CODE as transaction_uom,

pl.vendor_product_num,

pl.base_uom,

pl.base_qty,

pl.secondary_uom,

pl.secondary_qty,

pll.ship_to_organization_id,

ph.po_header_id,

ph.po_header_id as transaction_source_id,

ph.po_header_id as SOURCE_HEADER_ID,

pl.po_line_id as source_line_id,

pl.po_line_id,

pll.line_location_id,

pd.po_distribution_id,

msi.primary_unit_of_measure as UNIT_OF_MEASURE,

msi.serial_number_control_code,

DECODE(msi.serial_number_control_code,1,'No Control',2,'Predefined',5,'At Receipt',6,'At Issue','NA') serial_control,

msi.lot_control_code,

DECODE(msi.lot_control_code,1,'No Control','Full Control') lot_control,

pd.deliver_to_location_id,

pll.ship_to_location_id

FROM

apps.po_headers_all ph,

apps.po_lines_all pl,

apps.po_vendors pv,

apps.po_line_locations_all pll,

apps.po_distributions_all pd,

apps.mtl_system_items_b msi

WHERE

ph.po_header_id = pl.po_header_id

AND pl.po_line_id = pll.po_line_id

AND pd.line_location_id = pll.line_location_id

AND ph.vendor_id = pv.vendor_id

AND pl.item_id = msi.inventory_item_id

AND pll.ship_to_organization_id = msi.organization_id (+)

AND nvl(pl.closed_code,'OPEN') = 'OPEN'

AND pll.quantity - nvl(pll.quantity_cancelled,0) - nvl(pll.quantity_received,0) > 0

AND ph.authorization_status NOT IN (

'REJECTED'

)

AND pl.item_id IS NOT NULL

AND ph.org_id IN ('200','204')

UNION

SELECT

'PO' AS doc_type,

'RIKTRX' AS SOURCE_CODE,

ph.segment1 AS po_number,

'1' AS process_flag,

'2' AS lock_flag,

'3' AS transaction_mode,

'35' AS transaction_type_id,

'1' AS transaction_action_id,

'5' AS transaction_source_type_id,

'SYSDATE' AS creation_date,

'SYSDATE' AS last_update_date,

pl.line_num,

pll.shipment_num,

pv.vendor_name,

ph.currency_code,

ph.authorization_status,

pll.quantity - nvl(pll.quantity_cancelled,0) - nvl(pll.quantity_received,0) transaction_quantity,

NULL AS INVENTORY_ITEM,

pl.item_description,

pl.line_type_id,

DECODE(pll.receiving_routing_id,1,'STANDARD',2,'INSPECTION',3,'DIRECT',0,'NONE') routing,

DECODE(pll.receiving_routing_id,1,'RECEIVE',2,'RECEIVE',3,'DELIVER',0,'RECEIVE') AUTO_TRANSACT_CODE,

'RECEIVE' TRANSACTION_TYPE,

pd.destination_type_code,

pd.destination_subinventory,

NULL destination_locator,

NULL destination_locator_id,

pd.destination_organization_id as organization_id,

pl.purchase_basis,

pl.matching_basis,

pl.quantity line_qty,

pll.quantity,

pll.quantity_received,

pll.quantity_accepted,

pll.quantity_rejected,

pll.quantity_billed,

pll.quantity_cancelled,

ph.comments,

ph.document_creation_method,

ph.segment2,

ph.segment3,

ph.vendor_id,

ph.vendor_site_id,

ph.ship_via_lookup_code,

ph.fob_lookup_code,

ph.freight_terms_lookup_code,

ph.note_to_authorizer,

ph.note_to_vendor,

ph.note_to_receiver,

ph.vendor_order_num,

ph.org_id,

nvl(pll.promised_date,pll.need_by_date) AS promisdate,

pl.closed_code,

pl.unit_price,

pl.item_id as inventory_item_id,

pl.item_revision,

pl.unit_meas_lookup_code,

NULL as transaction_uom,

pl.vendor_product_num,

pl.base_uom,

pl.base_qty,

pl.secondary_uom,

pl.secondary_qty,

pll.ship_to_organization_id,

ph.po_header_id,

ph.po_header_id as transaction_source_id,

ph.po_header_id as SOURCE_HEADER_ID,

pl.po_line_id as source_line_id,

pl.po_line_id,

pll.line_location_id,

pd.po_distribution_id,

NULL as UNIT_OF_MEASURE,

NULL serial_number_control_code,

NULL serial_control,

NULL lot_control_code,

NULL lot_control,

pd.deliver_to_location_id,

pll.ship_to_location_id

FROM

apps.po_headers_all ph,

apps.po_lines_all pl,

apps.po_vendors pv,

apps.po_line_locations_all pll,

apps.po_distributions_all pd

WHERE

ph.po_header_id = pl.po_header_id

AND pl.po_line_id = pll.po_line_id

AND pd.line_location_id = pll.line_location_id

AND ph.vendor_id = pv.vendor_id

AND nvl(pl.closed_code,'OPEN') = 'OPEN'

AND pll.quantity - nvl(pll.quantity_cancelled,0) - nvl(pll.quantity_received,0) > 0

AND ph.authorization_status NOT IN (

'REJECTED'

)

AND pl.item_id IS NULL

AND ph.org_id IN ('200','204')

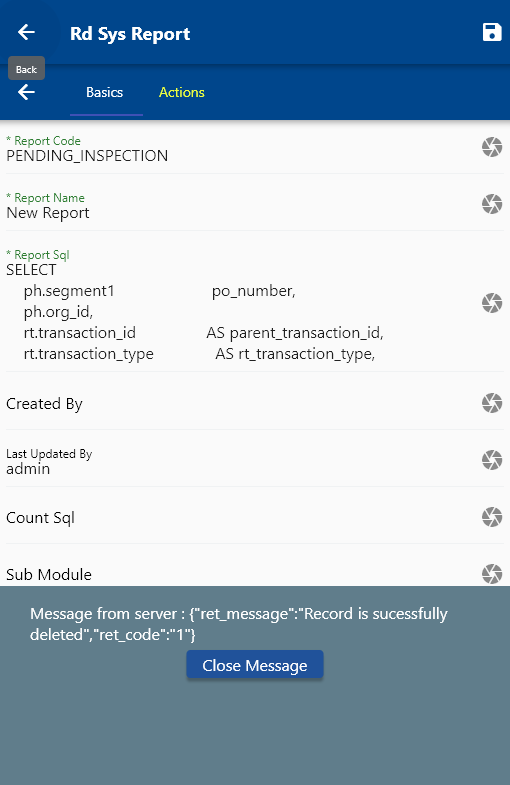

Pending Inspection

The pending inspection report shows all the items that have been received and waiting for inspection. Below is a sample SQL; you can modify it as per your business requirements.

SELECT

ph.segment1 AS po_number,

ph.org_id,

rt.transaction_id AS parent_transaction_id,

rt.transaction_type AS rt_transaction_type,

rt.transaction_date,

rt.quantity,

rt.unit_of_measure,

rt.shipment_header_id,

rt.shipment_line_id,

rt.source_document_code,

rt.destination_type_code AS rt_destination_type_code,

rt.employee_id,

rt.parent_transaction_id AS rt_parent_transaction_id,

rt.po_header_id,

rt.po_line_id,

pl.item_id,

pl.category_id,

rt.po_line_location_id,

rt.po_distribution_id,

rt.routing_header_id,

rt.vendor_id,

rsh.ship_to_org_id,

rsh.receipt_num,

rt.vendor_site_id,

'PO' AS doc_type,

'RIKTRX' AS source_code,

'1' AS process_flag,

'2' AS lock_flag,

'3' AS transaction_mode,

'35' AS transaction_type_id,

'1' AS transaction_action_id,

'5' AS transaction_source_type_id,

'SYSDATE' AS creation_date,

'SYSDATE' AS last_update_date,

ph.segment1 AS document_num,

pl.line_num AS document_line_num,

pll.shipment_num AS document_shipment_line_num,

pl.line_num,

pll.shipment_num,

pv.vendor_name,

ph.currency_code,

ph.authorization_status,

nvl(pll.quantity_accepted, 0) transaction_quantity,

msi.segment1 AS inventory_item,

msi.segment1 AS item_num,

pl.item_description,

pl.line_type_id,

decode(pll.receiving_routing_id, 1, 'STANDARD', 2, 'INSPECTION',

3, 'DIRECT', 0, 'NONE') routing,

'ACCEPT' transaction_type,

'ACCEPTED' inspection_status_code,

'Excellent' inspection_quality_code,

pd.destination_type_code,

pd.destination_subinventory,

NULL destination_locator,

NULL destination_locator_id,

pd.destination_organization_id AS organization_id,

pd.destination_organization_id AS to_organization_id,

pl.purchase_basis,

pl.matching_basis,

pl.quantity line_qty,

pll.quantity AS shipment_qty,

pll.quantity_received,

pll.quantity_accepted,

pll.quantity_rejected,

pll.quantity_billed,

pll.quantity_cancelled,

ph.comments,

ph.document_creation_method,

ph.segment2,

ph.segment3,

ph.ship_via_lookup_code,

ph.fob_lookup_code,

ph.freight_terms_lookup_code,

ph.note_to_authorizer,

ph.note_to_vendor,

ph.note_to_receiver,

ph.vendor_order_num,

nvl(pll.promised_date, pll.need_by_date) AS promisdate,

pl.closed_code,

pl.unit_price,

pl.item_id AS inventory_item_id,

pl.item_revision,

pl.unit_meas_lookup_code,

msi.primary_unit_of_measure AS primary_unit_of_measure,

msi.primary_uom_code AS transaction_uom,

pl.vendor_product_num,

pl.base_uom,

pl.base_qty,

pl.secondary_uom,

pl.secondary_qty,

pll.ship_to_organization_id,

ph.po_header_id AS transaction_source_id,

ph.po_header_id AS source_header_id,

pl.po_line_id AS source_line_id,

pll.line_location_id,

msi.serial_number_control_code,

decode(msi.serial_number_control_code, 1, 'No Control', 2, 'Predefined',

5, 'At Receipt', 6, 'At Issue', 'NA') serial_control,

msi.lot_control_code,

decode(msi.lot_control_code, 1, 'No Control', 'Full Control') lot_control,

pd.deliver_to_location_id,

pll.ship_to_location_id

FROM

apps.po_headers_all ph,

apps.po_lines_all pl,

apps.po_line_locations_all pll,

apps.po_distributions_all pd,

apps.po_vendors pv,

apps.rcv_transactions rt,

apps.rcv_shipment_headers rsh,

apps.mtl_system_items_b msi

WHERE

1 = 1

AND ph.po_header_id = pl.po_header_id

AND ph.vendor_id = pv.vendor_id

AND pl.po_line_id = pll.po_line_id

AND pd.line_location_id = pll.line_location_id

AND rt.po_line_id = pl.po_line_id

AND rt.po_header_id = ph.po_header_id

AND pll.line_location_id = rt.po_line_location_id

AND pd.po_distribution_id = rt.po_distribution_id

AND rt.shipment_header_id = rsh.shipment_header_id

AND pl.item_id = msi.inventory_item_id

AND pll.ship_to_organization_id = msi.organization_id

AND rt.transaction_type = 'RECEIVE'

AND pll.receiving_routing_id = 2

AND ph.org_id IN ('200','204')

Misc Receipt

The Misc Receipt report shows all the items available for misc receipt. Below is a sample SQL; you can modify it as per your business requirements.

SELECT

ood.organization_code,

'Miscellaneous Receipt' AS source_code,

msi.segment1 AS inventory_item,

msi.primary_uom_code AS transaction_uom,

'1' AS primary_quantity,

NULL AS account_combination,

substr(msi.description, 0, 70) AS item_dec,

decode(msi.planning_make_buy_code, 1, 'Make', 2, 'Buy') AS make_buy,

msi.cumulative_total_lead_time AS leadtime,

NULL AS dst_segment1,

NULL AS dst_segment2,

NULL AS dst_segment3,

NULL AS dst_segment4,

NULL AS dst_segment5,

NULL AS dst_segment6,

NULL AS dst_segment7,

NULL AS dst_segment8,

NULL AS dst_segment9,

msi.inventory_item_id,

msi.organization_id,

'1' AS process_flag,

'2' AS lock_flag,

'3' AS transaction_mode,

'42' AS transaction_type_id,

'SYSDATE-1' AS creation_date,

'SYSDATE-1' AS last_update_date,

'SYSDATE-1' AS transaction_date,

NULL AS transaction_interface_id,

NULL AS source_header_id,

NULL AS source_line_id

FROM

apps.mtl_system_items_b msi,

apps.org_organization_definitions ood

WHERE

1 = 1

AND msi.organization_id = ood.organization_id

AND msi.organization_id IN ( '204', '207' )

ORDER BY

msi.segment1

Misc Issue

The Misc Issue report shows all the items available for misc issue. Below is a sample SQL; you can modify it as per your business requirements.

SELECT

ood.organization_code,

'Miscellaneous Issue' AS source_code,

msi.segment1 AS inventory_item,

msi.primary_uom_code AS transaction_uom,

'1' AS primary_quantity,

NULL AS account_combination,

moqd.subinventory_code,

moqd.locator_id,

moqd.transaction_quantity,

substr(msi.description, 0, 70) AS item_dec,

decode(msi.planning_make_buy_code, 1, 'Make', 2, 'Buy') AS make_buy,

NULL AS dst_segment1,

NULL AS dst_segment2,

NULL AS dst_segment3,

NULL AS dst_segment4,

NULL AS dst_segment5,

NULL AS dst_segment6,

NULL AS dst_segment7,

NULL AS dst_segment8,

NULL AS dst_segment9,

msi.inventory_item_id,

msi.organization_id,

'1' AS process_flag,

'2' AS lock_flag,

'3' AS transaction_mode,

'32' AS transaction_type_id,

'SYSDATE-1' AS creation_date,

'SYSDATE-1' AS last_update_date,

'SYSDATE-1' AS transaction_date,

NULL AS transaction_interface_id,

NULL AS source_header_id,

NULL AS source_line_id

FROM

apps.mtl_system_items_b msi,

apps.org_organization_definitions ood,

apps.mtl_onhand_quantities_detail moqd

WHERE

1 = 1

AND msi.organization_id = ood.organization_id

AND msi.inventory_item_id = moqd.inventory_item_id

AND msi.organization_id = moqd.organization_id

AND msi.organization_id IN ( '204', '207' )

ORDER BY

msi.segment1

Dispatch List

The Dispatch List report shows all open work orders. Below is a sample SQL; you can modify it as per your business requirements.

SELECT

went.wip_entity_name AS wo_number,

wo.operation_seq_num,

went.description AS wo_description,

msi.description AS fg_description,

msi.segment1 AS fg_item_number,

msi.primary_unit_of_measure,

msi.primary_uom_code,

wo.wip_entity_id,

wo.organization_id,

wo.operation_sequence_id,

wo.department_id,

bd.department_code,

bd.description AS dept_description,

bd.location_id,

wo.description,

wo.scheduled_quantity,

wo.quantity_completed,

wo.quantity_in_queue,

wo.quantity_running,

wo.quantity_waiting_to_move,

wo.quantity_rejected,

wo.quantity_scrapped,

wo.first_unit_start_date,

wo.first_unit_completion_date,

wo.last_unit_start_date,

wo.last_unit_completion_date,

wo.previous_operation_seq_num,

wo.next_operation_seq_num,

wo.count_point_type,

wo.backflush_flag,

wo.minimum_transfer_quantity,

wo.date_last_moved,

wo.attribute_category,

wo.attribute1,

wo.attribute2,

wo.attribute3,

wo.attribute4,

wo.attribute5,

wo.operation_yield,

wo.operation_yield_enabled,

wo.operation_completed,

wo.previous_operation_seq_id,

wo.skip_flag,

wo.cumulative_scrap_quantity,

wo.progress_percentage,

wo.employee_id,

wo.actual_start_date,

wo.actual_completion_date,

wo.projected_completion_date,

wo.check_skill,

route_cost_equal_flag,

'RIKTRX' AS source_code,

'1' AS process_flag,

'2' AS lock_flag,

'3' AS transaction_mode,

'35' AS transaction_type_id,

'1' AS transaction_action_id,

'5' AS transaction_source_type_id,

'SYSDATE' AS creation_date,

'SYSDATE' AS last_update_date,

went.wip_entity_id AS transaction_source_id,

went.wip_entity_id AS source_header_id

FROM

apps.wip_operations wo,

apps.wip_entities went,

apps.bom_departments bd,

apps.mtl_system_items_b msi

WHERE

1 = 1

AND wo.wip_entity_id = went.wip_entity_id

AND wo.organization_id = went.organization_id

AND wo.organization_id = bd.organization_id

AND wo.department_id = bd.department_id

AND went.primary_item_id = msi.inventory_item_id

AND wo.organization_id = msi.organization_id

Detailed Dispatch List

The Detailed Dispatch List report shows all open work orders. Below is a sample SQL; you can modify it as per your business requirements.

SELECT

went.wip_entity_name,

wo.operation_seq_num,

ood.organization_code,

went.wip_entity_id,

wo.operation_sequence_id,

wo.department_id,

wr.resource_id,

went.organization_id,

went.entity_type,

went.description,

went.primary_item_id,

msi.description AS fg_description,

msi.segment1 AS fg_item_number,

msi.primary_unit_of_measure,

msi.primary_uom_code,

bd.department_code,

bd.description dept_description,

wr.resource_seq_num,

br.resource_code,

br.description resource_desc,

bd.location_id,

wdj.last_update_date,

wdj.last_updated_by,

wdj.creation_date,

wdj.created_by,

wdj.source_line_id,

wdj.source_code,

wdj.status_type,

wdj.firm_planned_flag,

wdj.job_type,

wdj.wip_supply_type,

wdj.class_code,

wdj.material_account,

wdj.material_overhead_account,

wdj.resource_account,

wdj.outside_processing_account,

wdj.material_variance_account,

wdj.resource_variance_account,

wdj.outside_proc_variance_account,

wdj.std_cost_adjustment_account,

wdj.overhead_account,

wdj.overhead_variance_account,

wdj.scheduled_start_date,

wdj.date_released,

wdj.scheduled_completion_date,

wdj.date_completed,

wdj.date_closed,

nvl(wdj.net_quantity, 0) - nvl(wdj.quantity_completed, 0) available_to_complete_qty,

wdj.start_quantity,

wdj.quantity_completed,

wdj.quantity_scrapped,

wdj.net_quantity,

wdj.bom_reference_id,

wdj.routing_reference_id,

wdj.common_bom_sequence_id,

wdj.common_routing_sequence_id,

wdj.bom_revision,

wdj.routing_revision,

wdj.bom_revision_date,

wdj.routing_revision_date,

wdj.lot_number,

wdj.alternate_bom_designator,

wdj.alternate_routing_designator,

wdj.completion_subinventory,

wdj.completion_locator_id,

wdj.mps_scheduled_completion_date,

wdj.mps_net_quantity,

wdj.demand_class,

wdj.schedule_group_id,

wdj.build_sequence,

wdj.line_id,

wdj.project_id,

wdj.task_id,

wdj.kanban_card_id,

wdj.overcompletion_tolerance_type,

wdj.overcompletion_tolerance_value,

wdj.end_item_unit_number,

wdj.attribute_category,

wdj.attribute1,

wdj.attribute2,

wdj.attribute3,

wdj.attribute4,

wdj.attribute5,

wdj.attribute6,

wdj.attribute7,

wdj.attribute8,

wdj.attribute9,

wdj.attribute10,

wdj.attribute11,

wdj.attribute12,

wdj.attribute13,

wdj.attribute14,

wdj.attribute15,

wdj.po_creation_time,

wdj.priority,

wdj.due_date,

wdj.est_scrap_account,

wdj.est_scrap_var_account,

wdj.est_scrap_prior_qty,

wdj.due_date_penalty,

wdj.due_date_tolerance,

wdj.coproducts_supply,

wdj.parent_wip_entity_id,

wdj.asset_number,

wdj.asset_group_id,

wdj.rebuild_item_id,

wdj.rebuild_serial_number,

wdj.manual_rebuild_flag,

wdj.shutdown_type,

wdj.estimation_status,

wdj.requested_start_date,

wdj.notification_required,

wdj.work_order_type,

wdj.owning_department,

wdj.activity_type,

wdj.activity_cause,

wdj.tagout_required,

wdj.plan_maintenance,

wdj.pm_schedule_id,

wdj.last_estimation_date,

wdj.last_estimation_req_id,

wdj.activity_source,

wdj.serialization_start_op,

wdj.maintenance_object_id,

wdj.maintenance_object_type,

wdj.maintenance_object_source,

wdj.material_issue_by_mo,

wdj.scheduling_request_id,

wdj.issue_zero_cost_flag,

wdj.eam_linear_location_id,

wdj.actual_start_date,

wdj.expected_hold_release_date,

wdj.expedited,

wdj.job_note,

wr.usage_rate_or_amount,

wr.basis_type,

wr.uom_code,

wr.activity_id,

wr.assigned_units,

wr.autocharge_type,

wr.standard_rate_flag,

wr.applied_resource_units,

( nvl(wdj.start_quantity, 0) * nvl(wr.usage_rate_or_amount, 0) ) - nvl(wr.applied_resource_units, 0) resource_transaction_qty

FROM

apps.wip_discrete_jobs wdj,

apps.wip_entities went,

apps.wip_operations wo,

apps.org_organization_definitions ood,

apps.mtl_system_items_b msi,

apps.bom_departments bd,

apps.wip_operation_resources wr,

apps.bom_resources br

WHERE

1 = 1

AND went.wip_entity_id = wdj.wip_entity_id

AND went.organization_id = wdj.organization_id

AND went.organization_id = ood.organization_id

AND went.primary_item_id = msi.inventory_item_id

AND ood.organization_id = msi.organization_id

AND wo.wip_entity_id = went.wip_entity_id

AND wo.organization_id = bd.organization_id

AND wo.department_id = bd.department_id

AND wo.wip_entity_id = wr.wip_entity_id

AND wo.operation_seq_num = wr.operation_seq_num

AND br.organization_id = went.organization_id

AND br.resource_id = wr.resource_id

Enter Cycle Count

The Enter Cycle Count report shows all the items available for cycle count. Below is a sample SQL; you can modify it as per your business requirements.

SELECT

msi.segment1 AS item_number,

mcce.item_description,

sysdate AS count_date_current,

mcce.subinventory,

mcce.count_quantity_current,

mcce.count_due_date,

mcce.locator_id,

mcch.cycle_count_header_name,

mcce.cycle_count_entry_id,

mcce.count_list_sequence,

mcce.restrict_locators_code,

mcce.inventory_item_id,

mcce.lot_control_code,

mcce.revision_qty_control_code,

mcce.uom_type,

mcce.primary_uom_code,

mcce.location_control_code,

mcce.positive_measurement_error,

mcce.serial_number_control_code,

mcce.entry_status_code,

mcce.organization_id,

mcce.cycle_count_header_id,

mcce.restrict_subinventories_code,

mcce.number_of_counts,

mcce.adjustment_quantity,

mcce.serial_detail,

mcce.approval_condition,

mcce.abc_class_id,

mcce.abc_class_name,

mcce.approval_status,

mcce.count_status,

mcce.cost_group_id,

mcce.cost_group_name

FROM

apps.mtl_cycle_count_entries_v mcce,

apps.mtl_system_items_b msi,

apps.mtl_cycle_count_headers mcch

WHERE

1 = 1

AND msi.inventory_item_id = mcce.inventory_item_id

AND msi.organization_id = mcce.organization_id

AND mcch.organization_id = mcce.organization_id

AND mcch.cycle_count_header_id = mcce.cycle_count_header_id

AND mcce.count_status IN ( 'Uncounted', 'Recount' )

AND ( mcce.count_due_date IS NULL

OR mcce.count_due_date > sysdate - 5 )

Confirm Shipment

The Confirm Shipment report shows all the sales order lines available for ship confirmation. Below is a sample SQL; you can modify it as per your business requirements.

SELECT

wdd.source_header_number,

wdd.source_line_number,

ooh.order_number,

ool.line_number,

ooh.ordered_date,

ooh.flow_status_code,

msi.segment1 AS inventory_item,

msi.description,

ool.ordered_quantity,

decode(wdd.source_code, 'OE', 'ORDER ENTRY', 'ORDER ENTRY') AS source_code,

wdd.source_header_id,

wdd.source_line_id,

'1' AS process_flag,

'2' AS lock_flag,

'3' AS transaction_mode,

'33' AS transaction_type_id,

'1' AS transaction_action_id,

'2' AS transaction_source_type_id,

wdd.organization_id,

ool.inventory_item_id,

wdd.picked_quantity AS transaction_quantity,

wdd.requested_quantity_uom AS transaction_uom,

wdd.subinventory AS subinventory_code,

wdd.locator_id,

wdd.source_line_id AS trx_source_line_id,

wdd.source_header_id AS transaction_reference,

mso.sales_order_id AS transaction_source_id,

ool.unit_selling_price,

ooh.sold_to_org_id,

ooh.ship_to_org_id,

ooh.invoice_to_org_id,

wdd.delivery_detail_id,

wdd.source_header_type_id,

wdd.source_header_type_name,

wdd.cust_po_number,

wdd.src_requested_quantity,

wdd.src_requested_quantity_uom,

wdd.lot_number,

wdd.released_status,

wdd.serial_number,

wdd.project_id,

wdd.task_id,

wdd.org_id

FROM

apps.wsh_delivery_details wdd,

apps.oe_order_headers_all ooh,

apps.oe_order_lines_all ool,

apps.hz_cust_accounts hca,

apps.mtl_system_items msi,

apps.mtl_sales_orders mso

WHERE

1 = 1

AND wdd.source_header_id = ooh.header_id

AND wdd.source_line_id = ool.line_id

AND ooh.header_id = ool.header_id

AND ooh.sold_to_org_id = hca.cust_account_id

AND msi.inventory_item_id = ool.inventory_item_id

AND msi.organization_id = ool.ship_from_org_id

AND wdd.released_status = 'Y'

AND mso.segment1 = ooh.order_number

AND mso.segment2 = wdd.source_header_type_name

Pending Delivery

The Pending Delivery report shows all the items available for delivery. Below is a sample SQL; you can modify it as per your business requirements.

SELECT

ph.segment1 AS po_number,

ph.org_id,

rt.transaction_id AS parent_transaction_id,

rt.transaction_type AS rt_transaction_type,

rt.transaction_date,

rt.quantity,

rt.unit_of_measure,

rt.shipment_header_id,

rt.shipment_line_id,

rt.source_document_code,

rt.destination_type_code AS rt_destination_type_code,

rt.employee_id,

rt.parent_transaction_id AS rt_parent_transaction_id,

rt.po_header_id,

rt.po_line_id,

pl.item_id,

pl.category_id,

rt.po_line_location_id,

rt.po_distribution_id,

rt.routing_header_id,

rt.vendor_id,

rsh.ship_to_org_id,

rsh.receipt_num,

rt.vendor_site_id,

'PO' AS doc_type,

'RIKTRX' AS source_code,

'1' AS process_flag,

'2' AS lock_flag,

'3' AS transaction_mode,

'35' AS transaction_type_id,

'1' AS transaction_action_id,

'5' AS transaction_source_type_id,

'SYSDATE' AS creation_date,

'SYSDATE' AS last_update_date,

ph.segment1 AS document_num,

pl.line_num AS document_line_num,

pll.shipment_num AS document_shipment_line_num,

pl.line_num,

pll.shipment_num,

pv.vendor_name,

ph.currency_code,

ph.authorization_status,

nvl(pll.quantity_accepted, 0) AS transaction_quantity,

msi.segment1 AS inventory_item,

msi.segment1 AS item_num,

pl.item_description,

pl.line_type_id,

decode(pll.receiving_routing_id, 1, 'STANDARD', 2, 'INSPECTION',

3, 'DIRECT', 0, 'NONE') routing,

'DELIVER' AS auto_transact_code,

'DELIVER' AS transaction_type,

pd.destination_type_code,

pd.destination_subinventory,

NULL AS destination_locator,

NULL AS destination_locator_id,

pd.destination_organization_id AS organization_id,

pd.destination_organization_id AS to_organization_id,

pl.purchase_basis,

pl.matching_basis,

pl.quantity AS line_qty,

pll.quantity AS shipment_qty,

pll.quantity_received,

pll.quantity_accepted,

pll.quantity_rejected,

pll.quantity_billed,

pll.quantity_cancelled,

ph.comments,

ph.document_creation_method,

ph.segment2,

ph.segment3,

ph.ship_via_lookup_code,

ph.fob_lookup_code,

ph.freight_terms_lookup_code,

ph.note_to_authorizer,

ph.note_to_vendor,

ph.note_to_receiver,

ph.vendor_order_num,

nvl(pll.promised_date, pll.need_by_date) AS promisdate,

pl.closed_code,

pll.closed_code AS shipment_closed_code,

pl.unit_price,

pl.item_id AS inventory_item_id,

pl.item_revision,

pl.unit_meas_lookup_code,

msi.primary_unit_of_measure AS primary_unit_of_measure,

msi.primary_uom_code AS transaction_uom,

pl.vendor_product_num,

pl.base_uom,

pl.base_qty,

pl.secondary_uom,

pl.secondary_qty,

pll.ship_to_organization_id,

ph.po_header_id AS transaction_source_id,

ph.po_header_id AS source_header_id,

pl.po_line_id AS source_line_id,

pll.line_location_id,

msi.serial_number_control_code,

decode(msi.serial_number_control_code, 1, 'No Control', 2, 'Predefined',

5, 'At Receipt', 6, 'At Issue', 'NA') AS serial_control,

msi.lot_control_code,

decode(msi.lot_control_code, 1, 'No Control', 'Full Control') AS lot_control,

pd.deliver_to_location_id,

pll.ship_to_location_id

FROM

apps.po_headers_all ph,

apps.po_lines_all pl,

apps.po_line_locations_all pll,

apps.po_distributions_all pd,

apps.po_vendors pv,

apps.rcv_transactions rt,

apps.rcv_shipment_headers rsh,

apps.mtl_system_items_b msi

WHERE

1 = 1

AND ph.po_header_id = pl.po_header_id

AND ph.vendor_id = pv.vendor_id

AND pl.po_line_id = pll.po_line_id

AND pd.line_location_id = pll.line_location_id

AND rt.po_line_id = pl.po_line_id

AND rt.po_header_id = ph.po_header_id

AND pll.line_location_id = rt.po_line_location_id

AND pd.po_distribution_id = rt.po_distribution_id

AND rt.shipment_header_id = rsh.shipment_header_id

AND pl.item_id = msi.inventory_item_id

AND pll.ship_to_organization_id = msi.organization_id

AND rt.transaction_type = 'ACCEPT'

AND ( pl.closed_code != 'CLOSED'

OR pl.closed_code IS NULL )

AND ( pll.closed_code != 'CLOSED FOR RECEIVING'

OR pll.closed_code IS NULL )

AND pll.receiving_routing_id = 2

AND ph.org_id IN ( '200', '204' )

UNION

SELECT

ph.segment1 AS po_number,

ph.org_id,

rt.transaction_id AS parent_transaction_id,

rt.transaction_type AS rt_transaction_type,

rt.transaction_date,

rt.quantity,

rt.unit_of_measure,

rt.shipment_header_id,

rt.shipment_line_id,

rt.source_document_code,

rt.destination_type_code AS rt_destination_type_code,

rt.employee_id,

rt.parent_transaction_id AS rt_parent_transaction_id,

rt.po_header_id,

rt.po_line_id,

pl.item_id,

pl.category_id,

rt.po_line_location_id,

rt.po_distribution_id,

rt.routing_header_id,

rt.vendor_id,

rsh.ship_to_org_id,

rsh.receipt_num,

rt.vendor_site_id,

'PO' AS doc_type,

'RIKTRX' AS source_code,

'1' AS process_flag,

'2' AS lock_flag,

'3' AS transaction_mode,

'35' AS transaction_type_id,

'1' AS transaction_action_id,

'5' AS transaction_source_type_id,

'SYSDATE' AS creation_date,

'SYSDATE' AS last_update_date,

ph.segment1 AS document_num,

pl.line_num AS document_line_num,

pll.shipment_num AS document_shipment_line_num,

pl.line_num,

pll.shipment_num,

pv.vendor_name,

ph.currency_code,

ph.authorization_status,

nvl(pll.quantity_accepted, 0) AS transaction_quantity,

msi.segment1 AS inventory_item,

msi.segment1 AS item_num,

pl.item_description,

pl.line_type_id,

decode(pll.receiving_routing_id, 1, 'STANDARD', 2, 'INSPECTION',

3, 'DIRECT', 0, 'NONE') AS routing,

'DELIVER' AS auto_transact_code,

'DELIVER' AS transaction_type,

pd.destination_type_code,

pd.destination_subinventory,

NULL AS destination_locator,

NULL AS destination_locator_id,

pd.destination_organization_id AS organization_id,

pd.destination_organization_id AS to_organization_id,

pl.purchase_basis,

pl.matching_basis,

pl.quantity AS line_qty,

pll.quantity AS shipment_qty,

pll.quantity_received,

pll.quantity_accepted,

pll.quantity_rejected,

pll.quantity_billed,

pll.quantity_cancelled,

ph.comments,

ph.document_creation_method,

ph.segment2,

ph.segment3,

ph.ship_via_lookup_code,

ph.fob_lookup_code,

ph.freight_terms_lookup_code,

ph.note_to_authorizer,

ph.note_to_vendor,

ph.note_to_receiver,

ph.vendor_order_num,

nvl(pll.promised_date, pll.need_by_date) AS promisdate,

pl.closed_code,

pll.closed_code AS shipment_closed_code,

pl.unit_price,

pl.item_id AS inventory_item_id,

pl.item_revision,

pl.unit_meas_lookup_code,

msi.primary_unit_of_measure AS primary_unit_of_measure,

msi.primary_uom_code AS transaction_uom,

pl.vendor_product_num,

pl.base_uom,

pl.base_qty,

pl.secondary_uom,

pl.secondary_qty,

pll.ship_to_organization_id,

ph.po_header_id AS transaction_source_id,

ph.po_header_id AS source_header_id,

pl.po_line_id AS source_line_id,

pll.line_location_id,

msi.serial_number_control_code,

decode(msi.serial_number_control_code, 1, 'No Control', 2, 'Predefined',

5, 'At Receipt', 6, 'At Issue', 'NA') AS serial_control,

msi.lot_control_code,

decode(msi.lot_control_code, 1, 'No Control', 'Full Control') AS lot_control,

pd.deliver_to_location_id,

pll.ship_to_location_id

FROM

apps.po_headers_all ph,

apps.po_lines_all pl,

apps.po_line_locations_all pll,

apps.po_distributions_all pd,

apps.po_vendors pv,

apps.rcv_transactions rt,

apps.rcv_shipment_headers rsh,

apps.mtl_system_items_b msi

WHERE

1 = 1

AND ph.po_header_id = pl.po_header_id

AND ph.vendor_id = pv.vendor_id

AND pl.po_line_id = pll.po_line_id

AND pd.line_location_id = pll.line_location_id

AND rt.po_line_id = pl.po_line_id

AND rt.po_header_id = ph.po_header_id

AND pll.line_location_id = rt.po_line_location_id

AND pd.po_distribution_id = rt.po_distribution_id

AND rt.shipment_header_id = rsh.shipment_header_id

AND pl.item_id = msi.inventory_item_id

AND pll.ship_to_organization_id = msi.organization_id

AND rt.transaction_type = 'RECEIVE'

AND ( pl.closed_code != 'CLOSED'

OR pl.closed_code IS NULL )

AND ( pll.closed_code != 'CLOSED FOR RECEIVING'

OR pll.closed_code IS NULL )

AND pll.receiving_routing_id IN ( 1, 3 )

AND ph.org_id IN ( '200', '204' )